Some people confuse plexiglass with fiberglass, maybe because of their names, but they’ve distinct physical features and uses. However, they both have a relationship with glass. For example, fiberglass mainly consists of plastic but with a gloss coating.

Plexiglass, on the other side, is a synthetic sheet that acts as a replacer to glass. Both are a great option in whatever need to purchase them for. What are their features or differences? Read on and understand more.

Difference Between Plexiglass and Fiberglass

· Their Uses

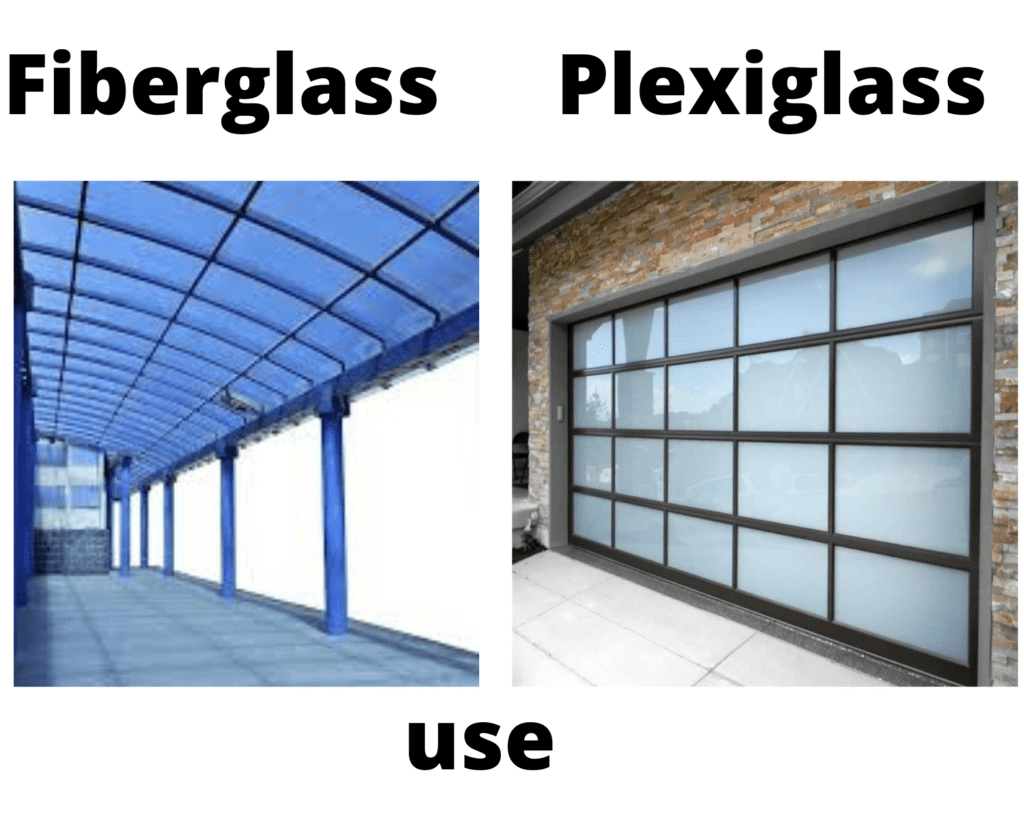

If you’re a manufacturer, you can use plexiglass material on your car or home windows to make lights and signs. You can also use it on furniture, bathtubs, and screens. Also, you can use it for producing appliances and eyewear lenses.

It is also helpful in medical industries to make prosthetics and other equipment. Moreover, it’s suitable for making various things in the airplane, lighthouse, and sports because of its strength.

On the other hand, you can use fiberglass for roofing on boats, aircraft, and windows. In addition, fiberglass helps hold up corrosive blood in chicken plants and grant bottle liners in the food and beverage industries.

Since fiberglass is slip-resistant, most chemical industries use it to make a conducive and safe work environment. And in the aviation industry, it’s best for making engine cowlings, storage bins, and bulkheads.

We also have reviewed the best blade for cutting plexiglass

· Production of fiberglass and plexiglass

Fiberglass, which is mainly plastic with glass, is produced by melting glass in various forms useful for a particular application. You can make it into thin threads and use it for insulating your home. You can also make it into clothes with different thicknesses and textures and use them for fiberglass fabrication. It’s robust, durable attractive, and affordable, a reason why most people prefer it.

Plexiglass is a synthetic polymer of methyl methacrylate or rather plastic. Its production involves warming in the oven then putting in a vacuum mold where air on its surface is removed. You can’t mold it into any other shape but rather cut it into the desired size.

· Features of Both Plexiglass and Fiberglass

Since plexiglass is a transparent plastic that’s a perfect glass replacement, it means it’s optically clear. It’s also weather and UV-resistant. Its lightweight and stability is the other feature that makes it easy to use. It’s also a good chemical resistant with high impact resistance.

What makes fiberglass different is its non-conductive nature, making it a good insulator. It’s also electromagnetic transparent to microwaves or radio waves. Fiberglass is also strong making it the best choice for making walkways or structures. You can also recycle, shape, or even use it to improve the surface finishing of various materials like mats.

We also have reviewed the best blade for cutting fiberglass.

What’re The Similarities Between the Two?

The main similarity between fiberglass and plexiglass is their strength and durability. If you use either of them, you’re sure they last before looking for a replacer or doing maintenance. In addition, you can use thick fiberglass to make car parts or hulls of boats because of its strength.

What makes plexiglass stronger is that it comprises various strengths with the materials for supporting the base, having undergone treatment using products that make it thick.

Plexiglass or Fiberglass?

The choice of which of these materials you will use in the situation at hand is entirely dependent on the use and manipulation. For instance, there isn’t much you can do with plexiglass but slice it into the size you want.

Fiberglass flexibility is to a high degree bearing in mind that you could shape sheets or even strip your desires. That is a significant reason why it helps in the creation of vehicles bodies.

Related Articles:

Last Updated on January 30, 2022 by John G. Anderson

Contents