A hole saw is a tool uniquely made for boring round holes of a bigger diameter than a typical bit. This tool features a cylinder-like saw blade fixed to an arbor. The purpose of an arbor is to grip the drill. There is usually a drill bit connected to the arbor for making a pilot hole or starter hole. The starter hole secures and aligns the saw blade.

The arbor and a drills chuck is the connection point between the hole saw and the drill. The hole saw is spun at terrific speed to create holes for different applications in various materials.

You will find a sea of options for hole saws both online and in outlets near you, and each type is suited for cutting specific materials.

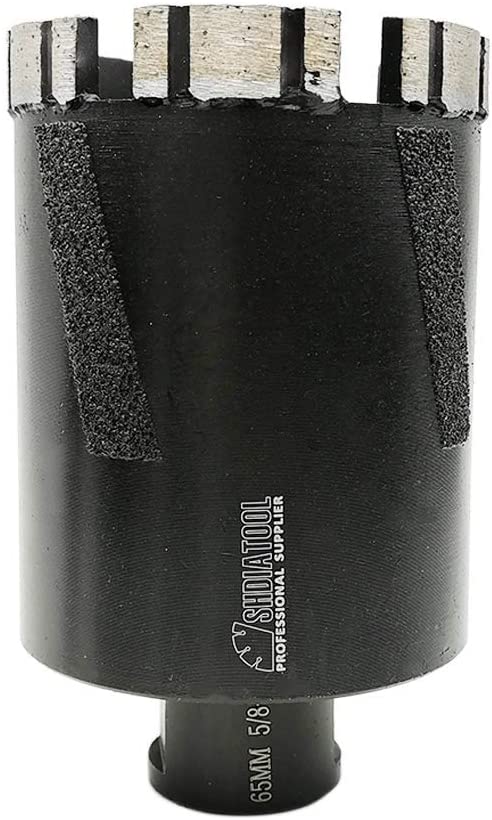

- Diamond Edge Hole Saws

Diamond Edge hole saws have no teeth; instead, their edges have a diamond entrustment or infusement. Hole saws crafted from Diamond are tough, long-lasting, high thermal and wear resistance. Their exhibit high performance and last longer despite consistent use with tough substances

These are suitable for professionals to aid in drilling holes in hard substances where conventional tools fail.They feature a circular shank that fits into any size of a drill chuck.

Though these types of hole cutters resist heat highly, it is advisable to cool the blades down with water spouts during use.

Diamond edge hole saws are suitable for cutting holes in ceramic tiles, granite, fiberglass, tiles, etc.

We also have reviewed best hole saw for fiberglass

2. Carbon steel hole saws

These are general-purpose low-budget hole saws for DIYers. They cut materials of ¾ inches thickness. They are not to be used on hard materials, only soft like wood and plasterboard. Carbon steel hole saws feature precision pointed teeth for smooth, chip-free, and accurate cuts.

They come in various diameters of 25- 68 mm and 30mm cut depth. Note also that the hardened alloy ( steel )cup is tampered to enhance durability.

They have a mandrel and a center drilling bit and a six-sided shank. It is usable with all typical power drills.

3. The Variable Pitch Bi-Metallic Hole Saws

These hole saws construction is exclusively for heavy use on various materials. They come with a hard alloy body from cobalt and hardened steel for durability. Sizes range between 9/16” – 6”.

They feature superior variable teeth pitch HSS teeth that resist abrasion. That allows for fast, and smooth, and chip-free hole cutting. These hole saws are safe to the user as they do not shatter from impact and regular use. Their cutting depth is mostly 30mm suitable for use with almost all (variable) speed drills. Why variable speed drills? that is to allow you to cut different materials at different speeds.

On the side are a sturdy beam weld and side vents that aid in the fast removal of plug or waste materials.

These are best for mechanics, plumbers, and heavy users. The wide array of materials you could cut using these hole saws include non-ferrous metal, plywood, plasterboards, hardwood, and many more.

4. Constant Pitch Hole Saws

These feature constant tooth pitch construction from hard, thermal, and abrasive resistant HSS (high-speed steel) and a tough alloy body. These are to be used with cell-powered drills of 18 volts. The constant (pitch tooth) geometry helps produce smooth and fewer splinters when boring metal, especially thin sheets. The saws hexagonal shank on its arbor bears a small indentation. The purpose of the indentation is to keep the shank locked tightly in the drill’s chuck.

Constant pitch hole saws are best for cutting thin plastic, wood, plasterboard, and stainless. Their cut depth is ½”and suits power tools without cords.

5.TungstenCarbide Grit Hole Saws

TCT( Tungsten carbide ) is notable for its high degree of toughness. These hole saws are versatile and very fitting for cutting rigid construction and masonry materials.

They feature unique square teeth with gullets. These teeth’ surface has a silicon carbide coating that easily cuts through highly abrasive and tough substances. Unlike typical teeth, the square teeth will not bite the materials being cut. That explains why you can cut hard materials such as ceramic without splintering.

Carbide grit hole saws are suitable to cut a wide variety of hard materials that include marble, minted plastics, late, marble, cast iron, plywood, etc.

6. Multi-Hole Saw Kit

The multi-hole saw types are made for cutting holes of various diameters. They can cut diameters of popular hole sizes starting from 63mm,56mm,50mm,45mm,38mm,32mm, and 26mm and a depth of 42mm. The hole saws can cut many types of materials, including chipboard, non-laminated plastics, plywood, and non-ferrous metal, apart from stainless steel. These have no restrictions on which power drills you can use.

7. Welded Shank (Soffit) Hole Saws

These come with their non-removable arbor fixed on their base. The hole saws are a combination of HSS and variable tooth pitch that make them ideal for boring holes on plywood, metal, and PVC. They come in 70mm diameter making them a perfect choice for cutting soffit boards to a depth of 1 7/8”.

To help you understand, Soffit refers to the downside area of a structure(architectural) that often needs vents drilled in them for installing drainage pipes.

8. Diamond Core Drilling Bits

These hole saws come with square-like teeth ingrained with diamond for an impressive cutting capacity. The wattage of drills used on these hole saws must fall within (850 – 1000)watts braced with a clutch for safety as well as a variable speed role.

These may require you to purchase its arbor separately.

The Diamond core drilling bits are ideal for boring neat holes in concrete or brick. Refrain from using impact drilling or hammer on these types of hole saws to avoid damages to its teeth.

We also have reviewed best hole saw for concrete

- Wet / Dry Diamond Core Drilling Bits

These drilling bits could be used either for dry and wet drilling to produce well-rounded holes in various construction materials. They are suitable for hand power tools whose wattage ranges within (800 -1500)watts. High wattage must be used on these core drilling bits to give them the power to cut the extra hard masonry materials. They are suited for use in concrete, granite, and other masonry materials.

In wet drilling, a lot of water is needed to cool down the core drilling bits from the heat caused by friction. The application of water helps increase the lifespan of the tool and prevent it from getting blunt.

For dry drilling, no water is used while making holes in materials.

Related Articles:

Last Updated on January 30, 2022 by John G. Anderson