Choosing the best combination table saw blade is quite easy when you know the right features and products for your ripping and crosscutting operations. Therefore we have collated durable and highly rated combination blades. We also discussed the features that make them outstanding, such as the teeth orientation, blade shape, high-tech laser-cut innovation, coating type, materials used for the blade tips, and application amidst other factors.

Our Top Pick is a 10″ Freud Thin Kerf Combination blade suitable for an underpowered saw and also has a reduced kickback design and a perma-shield coating while producing high-tech laser cuts. Our premium pick is a Freud 10″ kerf combination blade. It has a standard blade, a whooping speed of 8000rpm max, and a silver ICE coating. If you are low on budget, the 10” Dewalt combination blade is a perfect pick, having a tough coating, large carbide, and thin kerf.

Let’s have a look at these combination tables saw blades suitable for your woodworking operations.

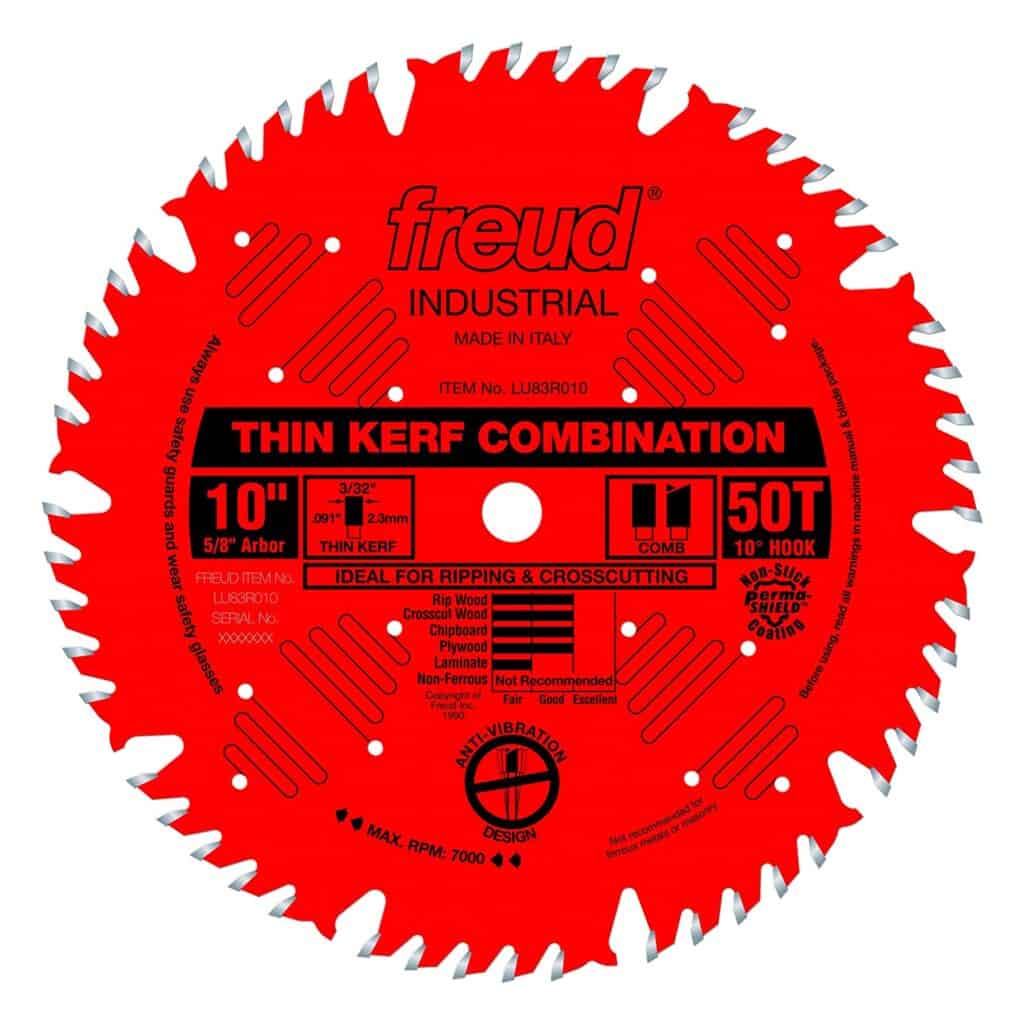

- Top Pick – Freud 10″ x 50T Thin Kerf Combination Blade

- Best Budget – DEWALT DW7150PT 10-Inch 50 Tooth ATB Combination Saw Blade

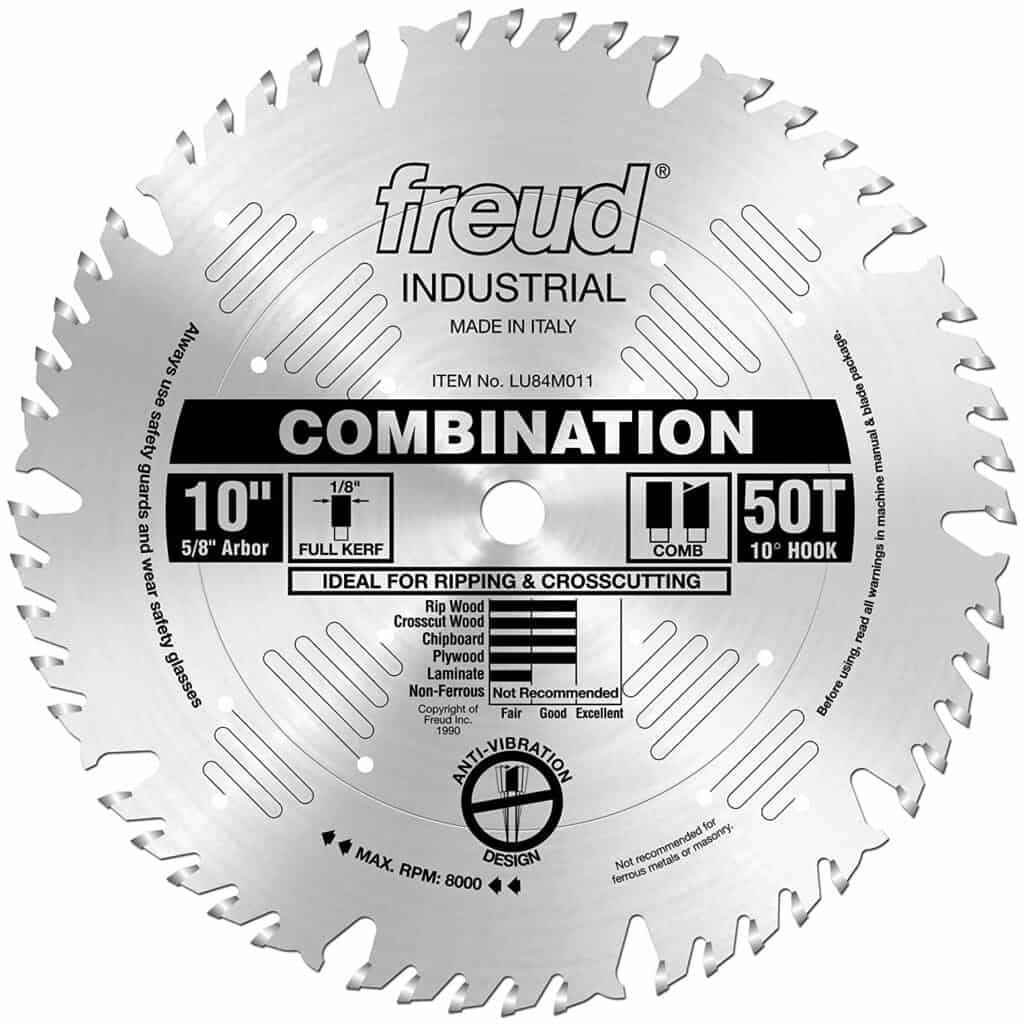

- Premium choice – Freud 10″ x 50T Combination Blade(LU84M011)

- 8 inch blade – Freud 8″ x 40T Thin Kerf Combination Blade

- 12 inch – Diablo D1260X Combination Saw Blade

- best industrial blade – CMT 256.050.10 ITK Industrial Combination Saw Blade

6 Best Combination Table Saw Blade

1. Freud 10” Thin Kerf Combination Blade

Key Features:

- Laser-Cut Anti-Vibration Slots and Vents

- Premium high-density Titanium Cobalt Carbide tips

- Tri-Metal Brazing

- Premium Permanent Shield Blade Coatings

- High Tech Laser Cuts

- Reduced Kickback Design

- Diameter: 10”, Arbor: 5/8”, Hook Angle: 10°, Teeth: 50, Thin Kerf: .091”, Plate: .071”

Are you interested in ripping thick materials between 3/8 to 1 inches or crosscutting materials between ¾ to 3 inches? Then this branded Italian combination blade is an ideal pick. It has a sharp flat riping tooth, followed by four ATB crosscutting teeth, while it uses large gullets for quick and chip clearance. Except for ferrous and non-ferrous materials, the blade is highly recommended for any material and could be for ripping or crosscutting woods, chipboard, plywood, and laminate.

This Freud thin kerf blade happens to be our top because of the quality materials and innovation used in fabricating this blade. From the laser-cut anti-vibration, which reduces sideways movement to the barest minimum, or to think about the thin kerf that aids faster feed rate, and at a less power consumption rate. This fabricated high-strength steel blade (HRC 46 to HRC 48) from a high-performance laser-cut runs at a max of 7000rpm and is highly durable. The teeth of the blade have high TiCo Hi-density Carbide edges that are very sharp and have a reduced rate of wear, resistance to corrosion, heat, and any form of impact. Thanks to its advanced micro-grain Carbide tips formulated from the blend of Titanium Carbide, Cobalt, Tungsten, and some other elements, thus this blade is suitable for varieties of operations.

Some other features like the tri-metal brazing, reduced kickback designs, and Perma shield coating, make this blade versatile, well balanced and deliver accurate cuts. The premium coating feature protects the blade against corrosion and reduces blade drag, which increases the blade’s lifespan. The kickback design also prevents dangerous kickbacks, and its tri-metal brazing binds the steel blade, and the carbide tips allow for extra flexibility and resistance to impact.

Pros:

- No need for a stabilizer for blade stability

- The thin kerf blade is more efficient than most standard blades

- It produces quiet and smooth cuts

- It has less vibration

Con:

- Not a perfect pick for a compound miter saw.

2. Dewalt 10” Combination Blade

Key Features:

- Laser-Cut Anti-Vibration Slots

- Exclusive Plate Technology

- Premium high density 2x large carbide

- High Tech Laser Cuts

- Tough coat finish

- Diameter – 10”, Arbor- 5/8”, Hook Angle – 15°, Teeth- 50, Thin Kerf: .098”, Plate: .071”

Unlike the Freud 10” combination blade, this blade fabricated in the U.S.A works perfectly on non-ferrous materials. It can also be used on wooden materials and plastic and has a large carbide. Fortunately, getting this blade saves you from massive spending as it cost as low as $33.

At this low cost, it also has a comparatively high speed of 6000rpm at a bit less than its Freud counterpart. Thus, the price and other top innovations make it the best value for your money in this review.

Its tough and anti-sticky coat guarantees its user a reduced level of heat, friction, pitch build-up while ripping or crosscutting, and rust when stored. Thus, it extends blade life and makes cleaning the blade easy. Like some other blades, the thin kerf allows the user to perform a clean and smooth finish during cutting operations. And this is done at a low power consumption rate and with a minimized material waste rate. Further, splintering is drastically reduced by the large micro-grain carbide teeth it possesses and ensures ultra-sharp cutting edges.

This blade cuts about 4” and is well balanced during cutting operations. The dampening slot allows for a low noise and vibration level, which enhances accurate cuts. Its heavy gauge, precision balanced laser cut tempered steel plate mainly helps make precise cuts, even in tight areas.

Pros:

- The blade has a great feed rate and superfast

- Suitable for making clean and accurate cuts

- Compatible with a riving knife

- Its vibration level is negligible

Con

- Not ideal for flat bottom dado

3. Freud 10” Kerf Industrial Combination Blade

Key Features:

- Premium high-density Titanium Cobalt Carbide tips

- Silver ICE Coatings

- Laser-Cut Anti-Vibration Slots and Vents

- High Tech Laser Cuts

- Reduced Kickback Design

- Diameter: 10”, Arbor: 5/8”, Hook Angle : 10°, Teeth: 50, Kerf: .126”, Plate: .087”

This Freud full kerf combination blade is another Freud blade on our list. It has few notable differences when compared to our top pick, the thin kerf Freud blade. Some of the vital differences are in the rpm, kerf, and blade coating types. The speed of this blade is 8000 rpm, higher than the 7000rpm of the thin kerf Freud blade. Further, this blade uses an ice coating, different from the perma-shield used for the thin kerf blade. Thus, though this standard kerf blade has more speed, the thin kerf Freud blade has a better coating against pitch buildup, rust, and in turn, run cooler.

The full kerf is thick, wide and eliminates blade deflection while offering more precise cuts. This blade is our premium pick because of its width, speed, and innovations used by Freud in producing this blade. Though, this is not to say this combination blade is not pricey, as it cost about $78. Like other Freud products in this review, this is a multiple-purpose blade having a flat tooth for ripping followed by four alternate top bevel crosscutting teeth and a large gullet that does effective chips clearance. It’s suitable for riping materials of 3/8 to 1-1/2 inches thickness and crosscutting materials of ¾ to 3-1/2 inches thickness. It is ideal for working on woods, chipboard, plywood, and laminate, but not on ferrous and non-ferrous materials. Vibrations and noises, even under heavy loads, noticed in standard blades are greatly reduced with the laser cut anti-vibration slots feature while the blade is well balanced.

Users also get to enjoy long-lasting and sharp high-density carbide tips fabricated by Freud with a combination of Titanium Carbide, Cobalt, Tungsten, and some other elements. These tips are also resistant to heat impact and corrosion. Further, the teeth have edge retention that makes them stay longer than standard blades; this saves money and time.

Pros:

- No need for a stabilizer

- Very minimal splintering on wooden materials

- The blade is quiet during operations

- The blade cuts more accurate than the thin kerf blade

Con

- Often does not leave a flat bottom cut

4.Freud 8” Thin-Kerf Combination Blade

Key Features:

- Laser-Cut Anti-Vibration Slots and Vents

- Premium high-density Titanium Cobalt Carbide tips

- Premium non-sticking Perma-Shield Blade Coating

- High Tech Laser Cuts

- Reduced Kickback Design

- Diameter – 8”, Arbor- 5/8”, Hook Angle – 10°, Teeth: 40, Thin Kerf: .083”, Plate: .063”

One great advantage of this thin-kerf blade is that it operates with less power compared to a standard kerf blade and allows for a faster feed rate even with underpowered saw motors. The blade is a smaller combination blade compared to others in this review. It has a speed of 9000rpm max and is not ideal for very thick woods, but for ripping and crosscutting laminate, plywood, chipboard like other Freud blades, and is not suited for operations on ferrous and non-ferrous materials. It works well while riping materials of 3/8 to 1-1/2 inches thickness and crosscutting materials of 3/4 to 3-1/2 inches thickness. Using it outside this range might lead to some loss of surface finish.

The blade teeth are arranged like other Freud combination blades. A flat-top raker riping tooth with accurate cuts, four ATB teeth for crosscutting, and a large gullet that clears chips. And even with its price and low diameter, the blade is well balanced, thus no need for an add-on stabilizer. Users also enjoy quiet operations, a clean finish, and little or no side movement of the blade because of its anti-vibration slots. Unarguably, this feature elongates the lifespan of the table saw blade. The non-sticky perma-shield coating also elongates the lifespan while assisting in making smooth cuts, as it reduces friction, heat buildup, pitch buildup, and blade warp.

The tips of this blade tooth are of high-density carbide, which assists the user in maintaining sharp cutting edges, even when tried on a variety of applications and for a long time. It’s possible because, unlike other TiCo blends, the tips are formulated with a superior blend of high-density tungsten carbide and offer more resistance to heat, corrosion, and impacts.

Pros:

- Often leaves no smoke or burn marks

- Produces quiet and clean cuts

- It has a negligible level of splintering

Cons:

- It’s pricey when compared to some 12″ combination blades

- The blade is small and gets hooked when cutting anything on a bevel or angle.

5. Diablo 12” Combination Blade

Key Features:

- Laser-Cut Anti-Vibration Slots and Vents

- Premium Perma-Shield Blade Coatings

- Premium high-density TiCo Carbide tips

- Tri-Metal Shock Resistant Brazing

- Super thin laser cut kerf

- Hardened steel body

- Diameter : 12”, Arbor: 1”, Hook Angle: 15°, Teeth- 60, Thin Kerf: .118”, Plate: .071”

This blade is just the perfect fit for your table saw. It has 60 teeth, a speed of 6000rpm, and is another product of the Italian maestro brand in fabricating superior and high-quality carbide cutting tools – Freud, thus having many similar features to other features products in this review, but at a low price. For instance, the blade is covered with a perma-shield non-sticky coating that reduces all forms of friction, heat, and pitch build-up, blade binding when used for large volume cutting operations. This coating ensures a longer life span of the blade. Also, the blade’s tip is tough even in less than ideal circumstances.

This TiCo high-density carbide blade weighs 2.5 pounds more than any blade in this review. However, it performs like other thin-kerf blades; durable and has a longer cutting life than standard carbide. The blade tips can also withstand high impact because of their tri-metal shock-resistant brazing.

Further, this blade is not suitable for cutting ferrous metals or masonry but is ideal on hardwood, softwood, melamine, and plywood, perhaps when remodeling or demolishing. It rips grains accurately with a flat top raker tooth, has four ATB teeth for cutting across grains, and a large gullet for chip clearance.

Pros:

- The blade operates quietly

- It makes very accurate cuts

- The amount of wood wasted is little

- This blade is very sharp

6. CMT 10” Industrial Combination Blade

Key Features:

- Laser-Cut Heat Expansion Slots

- Laser-Cut Premium Quality Steel Plate Body

- Chrome Plated Blade

- Tri-Metal Brazing

- Slot Sound-Dampened Materials

- Precision Mirror Finishing Sharpener

- Diameter – 10”, Arbor- 5/8”, Hook Angle – 15°, Teeth- 50, Thin Kerf: .098”, Plate: .071”

Are you in search of a thin kerf blade for your underpowered saw, one that cuts very fast and has a quality finish? Check out this blade. It works with Miter saw, slide miter saw, stationary or moveable table, and is ideal for cutting operations on plywood, hard and softwoods, and laminates. It rips materials between – 1 and crosscut materials between – 3 and at a speed of 7600 max. Also, apart from the price being very cheap, the blade is a hardened laser cut heavy-duty blade plate with (46 – 48 Rockwell in hardness). Hence, it is tough to even in a less ideal situation. The teeth are brazed with a tri-metallic bond and are fabricated with micro-grain carbide, which makes the blade last longer and has high strength.

The innovation of the laser cut expansion slots used in this blade prevents blade warping and extending the blade’s life. To minimize noise and vibrations by 25% when compared to standard blades, the blade slots are filled with polyurethane. And in compliance with the regulations of the national Noise Emission Standard and Regulations, there is shock absorption and vibration isolation for slots closer to the toothed crown.

There is also a blade tensioning ring on its body which ensures well-balanced cuts. Each tooth is precise to provide perfect edge angles, fewer rough edges less than 0.25 µm Rmax, and extended life.

Pros:

- Quiet cutting operations than standard blades

- It has a level of precision while cuts

- Often leaves no smoke or burn marks

- The package comes with a CMT plastic case and instructional guide on resharpening.

Con:

- Sometimes does not leave a flat bottom surface.

How to choose best combination table saw blade

Are you confused about the essential features to look out for when purchasing a combination table saw? Then check out these factors below.

Thin Blade Kerf or Standard Blade Kerf:

A standard kerf saw blade is a saw blade whose carbide teeth are 1/8 inch wide. On the other hand, the carbide teeth for the thin kerf are 3/32 inches wide. The type of project and horsepower your saw motor can provide determines the kerf type to go purchase. If you are working on thin stripped projects, the thin kerf blade is ideal for your project; there is reduced wood wastage and reduced sawdust. Further, the thin kerf is suitable for underpowered motors or motors under 3HP. The full kerf or standard kerf is ideal for a precise cut on thick wood. There is no blade deflection as they are sturdy and durable. All the blades in this review are thin kerf, except for the Freud 10” Kerf Industrial Combination Blade.

Safety:

Safety is paramount, especially when using a saw blade. Our top pick is designed to reduce blade kickback. It is also important to budget for safety apparatus like safety glasses that protects you from flying chips while cutting. Other gears include head protection, hand gloves, and suitable footwear.

Blade Speed:

The speed of the matter also especially for quick cuts. Thus if you need a kerf blade with high max speed, the Freud 10″ Kerf Industrial Combination Blade is a good option with 8000rpm max. The Freud 8” Thin-Kerf Combination Blade has a speed of 9000rpm and is suitable if you need a thin kerf blade.

Price:

Especially for users having a low budget, price is a factor to consider. Therefore, we collated a blade with outstanding features and low prices. You can check out the Dewalt 10″ Combination Blade, available at $33.

Other factors to consider are the noise, vibration level, and coating. These ensure comfort, no pitch and heat buildup, smooth movement of the blade, and in turn, extended blade life. Interestingly, all listed blades in this review have these features.

If you are thinking of using a combination blade for the first time, you might have some questions to ask. So let’s go through some questions.

Frequently Asked Questions

What is a combination table saw blade?

A combination table saw blade is a blade having a flat tooth followed by alternate top bevel teeth and then a gullet. These parts assist a woodworker in ripping, crosscutting, and then for clearance of chips, respectively.

What are combination saw blades used for?

Combination saw blades are mainly used for cutting materials (ripping operations), cutting across materials (crosscutting), and for making cuts for corners or joints) mitering. These materials range from softwood, hardwood, veneers, plywood, to mention a few. Combination saw blades are suitable for woodworkers who do not need perfect cuts or are low on budget.

Thanks for reading through this review on the best combination table saw blade. We hope you got the information you need.

Related Articles:

Last Updated on January 23, 2022 by John G. Anderson

Contents